Lesintor Machine is a Chinese manufacturer of high-quality, reasonably priced plastic crusher machines. Powerful plastic crushing machines can be used for a wide range of plastic product crushing and recycling applications. Recycled plastic casing, plastic tubes, injection and mold industry, bottle plastics, and shell plastics are the product that can be produced with plastic crusher machine. It is mostly used in injection nozzle outlets or waste products of polymer foam soft material, PVC, polypropylene, nylon, and engineering plastics.

▎Wholesale Powerful Plastic Crusher Features:

- The crusher has many uses and can crush and recycle plastic products of various materials and shapes.

- Important parts, such as the box body and the frame, are reinforced to ensure accurate fit.

- Equipped with multiple safety protection devices to ensure safe operation.

- The feeding hopper is designed as a double layer to reduce noise.

- The power seat is a trapezoidal equipment design, so the cutting force decomposes and doubles.

- The heavy-duty bearing and oil seal device and the anti-sound partition can effectively prevent vibration and ensure that grease does not contaminate the loading.

- The motor has an overload protection system, and the power supply interlocking system has a cleaning tool protection system to ensure safety during cleaning.

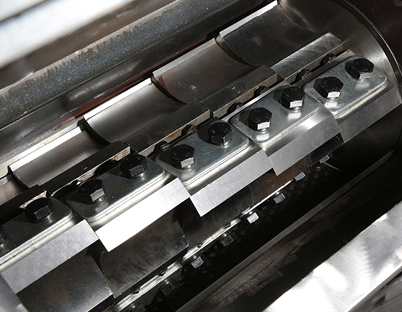

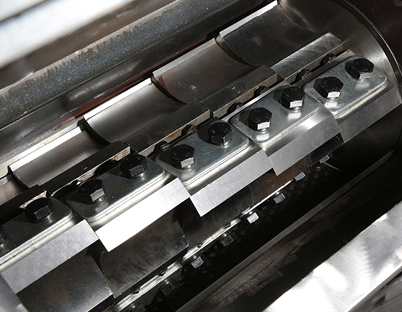

- The tool installation design can be adjusted telescopically. It can be sharpened many times after being blunted, used repeatedly, and has a long life.

- The blanking hopper, crushing chamber, and filter screen design are easy to disassemble and wash.

- The small crusher is equipped with casters, which make it convenient to move. The large crusher machine is equipped with adjustable shock-absorbing feet. These accessories can make the crusher work more stable.

▎Product Pictures

▎Crushing Effect Display

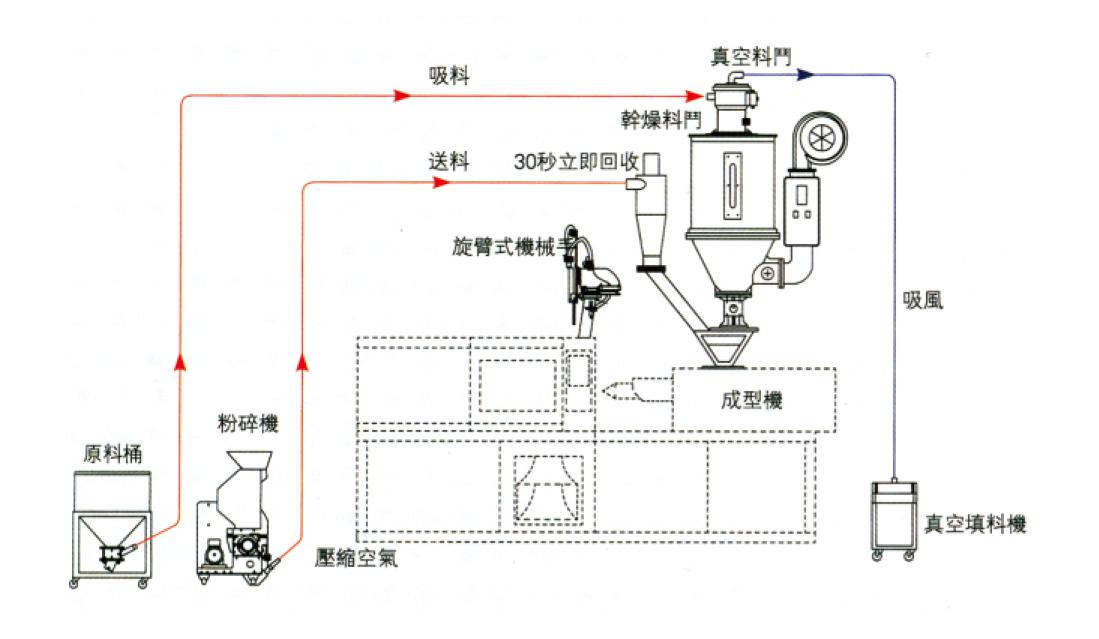

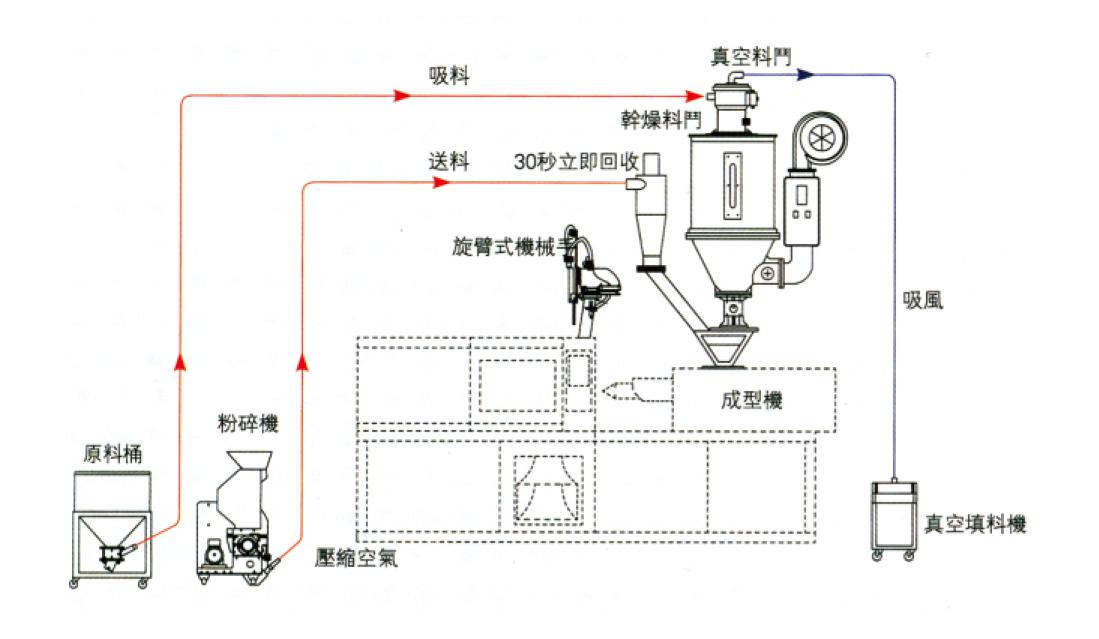

▎Application Example

▎Product Parameters

| Model |

QL300 |

QL400 |

QL500 |

QL600 |

QL700 |

QL800 |

QL1000 |

| Motor power |

KW |

5.5 |

7.5 |

11 |

15 |

22 |

30 |

37 |

| HP |

7 |

10 |

15 |

20 |

30 |

40 |

50 |

| Spindle speed (r/min) |

610 |

580 |

600 |

506 |

493 |

440 |

440 |

| Spindle diameter (mm) |

72 |

72 |

78 |

82 |

110 |

110 |

110 |

| Tool number(pcs) |

9 |

12 |

15 |

18 |

21 |

24 |

6 |

| Fixed cutter number (pcs) |

2 |

2 |

2 |

4 |

4 |

4 |

4 |

| Work efficiency(kg/h) |

150-200 |

250-400 |

300-500 |

500-600 |

600-700 |

700-800 |

900-1000 |

| Feed port size(mm) |

300*200 |

400*250 |

500*285 |

600*315 |

685*430 |

800*450 |

1000*500 |

| Machine weight(kg) |

300 |

430 |

550 |

800 |

1325 |

1800 |

2000 |

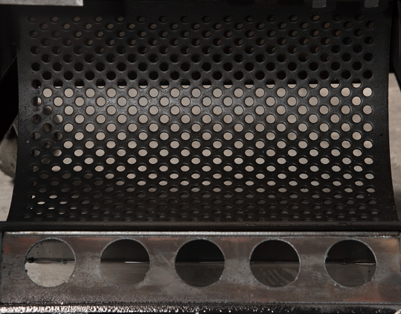

| Mesh diameter(mm) |

∅8 |

∅10 |

∅10 |

∅12 |

∅12 |

∅12 |

∅14 |

| Outline size(m) |

1.07*0.72*1.08 |

1.29*0.86*1.18 |

1.37*1.06*1.39 |

1.54*1.15*1.66 |

1.75*1.25*1.96 |

1.95*1.37*2.18 |

2.25*1.60*2.4 |

▎More details:

- Model 400 equipped with 4 cutters.

With a refined steel step cutter tool, the cutter gap can be adjusted, removed, and repeatedly sharpened after it has become dull.

- Model 500 equipped with 5 cutters.

Inside, alloy steel cutters are sharper and more durable.

|

|

Enlarged feed inlet

Double-layer retaining skin widened like a duckbill. Enlarged feed inlet, faster blanking, and more fierce punching

|

Cutter chamber

The Cutter chamber is made of thick materials, effectively preventing vibration and noise, and has a high environmental protection effect.

|

|

|

Large diameter flywheel

Equipped with a large flywheel and belt pulley, the motor can rotate at 1440 revolutions per minute and the cutter shaft at 576 revolutions per minute. Thus, it is extremely stable and suitable for crushing various plastics.

|

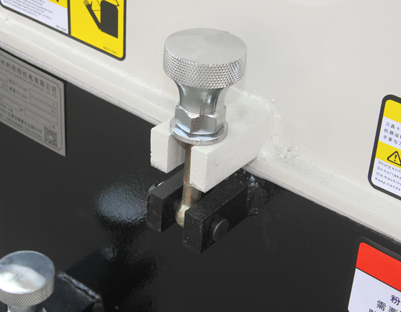

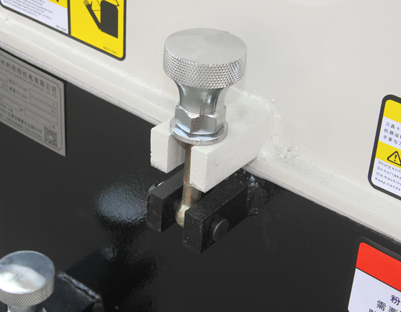

Locknut

Hand-tighten first and then tighten with a wrench; easy to operate, user-friendly design.

|

|

|

Extra Long Receiving Drawer

Enlarge and extend the drawer, which is 20 cm longer than the body, to store more materials and make it more convenient for customers to take them.

|

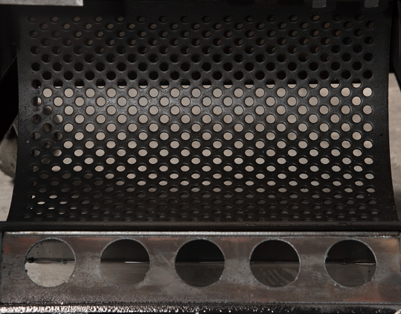

Customizable Screen

The output size depends on the screen mesh size, and the selection is more flexible.

|