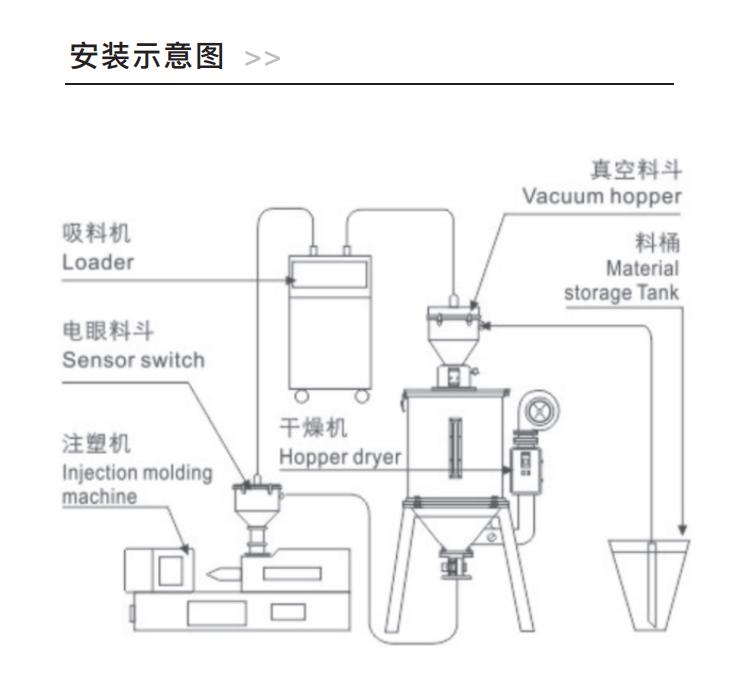

• One machine tows multiple buckets, saving equipment configuration and space. Vacuum and electric plastic hopper loader can be selected according to the actual use situation.

• Especially suitable for drying and feeding integrated systems, simplifying the system structure, improving the use efficiency and convenient operation.

• Fully automatic computer operation program.

• Integrated control, Easy to replace, Convenient debugging

• Convenient and fast maintenance.

| GB/T19001-2016/ISO9001:2015 "Management System Certification Certificate" |

| GB/T 24001-2016/ISO14001:2015 "Management System Certification Certificate" |

| CCTV advertising ID number:1962573230050061 "CCTV Advertising Broadcasting Certificate" |

| "Quality·Service·Integrity AAA Enterprise""National Key Recommended Products in China's Plastics Industry" |

1. Microcomputer control program, once set, can be permanently saved.

2. Standard micro switch, stainless steel hopper, 350 equipped with single-phase 220V high-speed imported motor and equipped with a three-phase induction type high-pressure positive blower.

3. Adopts nano non-woven filter, with the function of controller net cleaning, to realize the function of automatic electronic pulse dust removal. Equipped with a compressed gas storage tank, the back blowing is more powerful, the operation is more stable, and the effective cleaning does not need manual work.

4. The host machine has a fault display code, automatic diagnosis, and an overload alarm protection device.

Here are Lesintor's other popular related products. If you have any doubts, please contact us using our contact form.